In an age where efficiency and precision are at the forefront of production processes, the technology we employ must be nothing short of the best. Within the vast domain of manufacturing, blending and combining materials is a common yet critical step. Here is where industrial static mixers come into play. These powerful tools have revolutionized mixing technology and become indispensable to numerous industries. This article will take a deep dive into these technological marvels and explore how they can optimize your production processes.

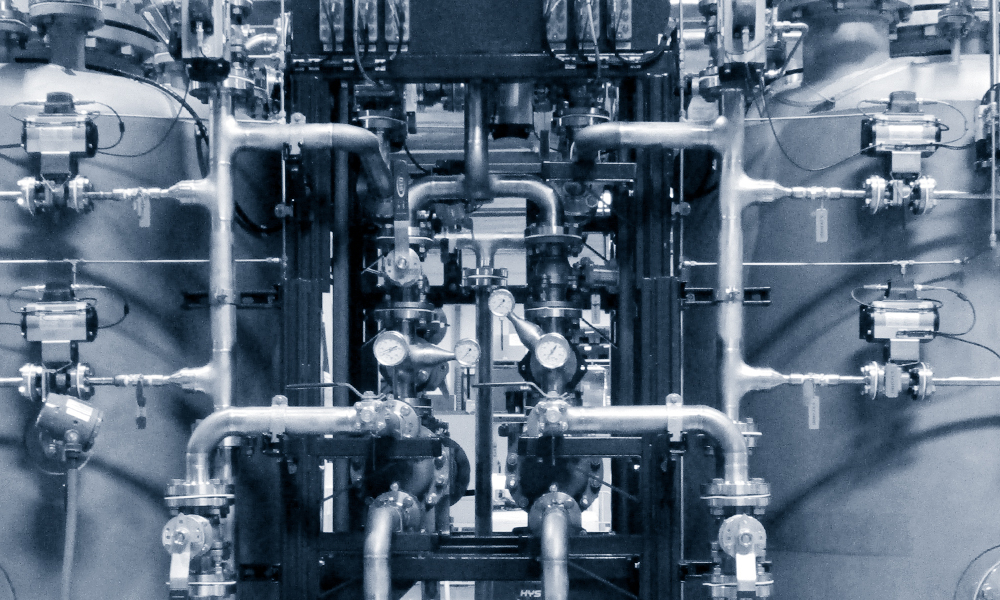

An Ingenious Design: How It Works

At the heart of these mixing titans is an ingenious design that is as simple as it is effective. Unlike their dynamic counterparts, these mixers don’t have any moving parts. Instead, they employ a series of fixed elements within a cylindrical housing. As materials flow through this housing, the elements continuously split, combine, and recombine the flow. This creates a highly homogenous mixture in a remarkably short time, with minimal energy consumption. This elegant design ensures superior mixing quality and drastically reduces maintenance needs. Furthermore, the stationary components minimize wear and tear, prolonging the mixer’s lifespan. The simplicity of the design also translates into ease of installation, ensuring that integration into existing systems is hassle-free.

Tailored for Excellence: Customization Options

Customization is key in ensuring that your mixing machinery meshes seamlessly with your specific production requirements. Whether blending viscous liquids in the chemical sector or mixing gases in the energy industry, these mixers can be tailored to suit your needs. Customizable parameters include the size and shape of the mixing elements, the construction material, and the mixer’s overall dimensions. By fine-tuning these parameters, you can achieve unparalleled mixing efficiency and quality.

Economical Powerhouse: Cost and Energy Efficiency

In the current competitive landscape, cutting costs while maintaining high standards of production is paramount. One of the most striking advantages of using industrial static mixers is their ability to significantly reduce both operational costs and energy consumption. The absence of moving parts means that maintenance and repair costs are kept to a minimum. This translates to significant cost savings in the long run, enabling your business to allocate resources to other critical areas for overall growth and development.

Diverse Applications: Versatility Across Industries

The applications of these mixers are as diverse as they are numerous. From the food and beverage sector, where they are used to combine syrups and concentrates, to the pharmaceutical industry, where they ensure that medicines are consistently blended. Their use in wastewater treatment plants to facilitate the mixing of chemicals is a testament to their versatility. What’s more, as industries continue to evolve and face new challenges, the adaptability of these mixers makes them poised to meet future demands head-on.

Environmental Stewardship: Contributing to Sustainability

Incorporating environmentally sustainable practices into production processes is no longer an option but a necessity. With their energy-efficient design, industrial static mixers contribute to reducing the carbon footprint of your production processes. Their ability to work effectively with minimal energy consumption means saving costs and contributing to a more sustainable and greener planet.

Conclusion

In the realm of mixing technology, industrial static mixers stand as titans. Their ingenious design ensures impeccable mixing quality, while the customization options allow for a seamless integration into virtually any production process. The economic and environmental benefits further cement their position as an essential asset in modern manufacturing. Their diverse applications show that they are not just efficient but versatile enough to meet the demands of a wide range of industries. Whether you are in the food, pharmaceutical, chemical, or any other industry, employing these mixers is a definitive step towards optimizing your production processes and contributing to a more sustainable future.

Comments