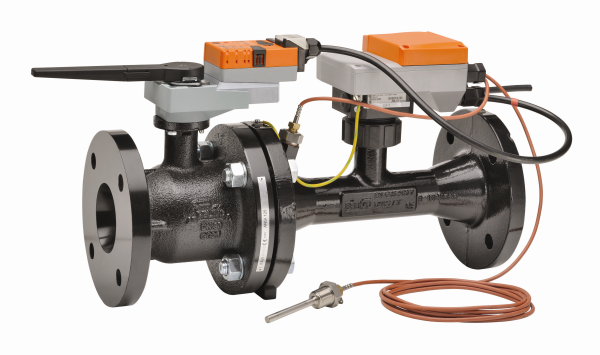

In today’s highly technological world, we often find ourselves marveling at the final products that make our lives easier and more efficient. However, we seldom pay attention to the conceptual frameworks and meticulous engineering that go into making these products a reality. A prime example of this intricate engineering is the technology behind Belimo CCV Valves.

The Origin: Why CCV Valves?

CCV Valves or Characterized Control Valves serve as a cornerstone in modern HVAC systems. They provide not just the basic on/off functionality, but also deliver precise control over fluid flows, optimal energy utilization, and long-lasting durability. Before these valves become part of your HVAC systems, they go through several stages of conceptualization, design, testing, and finally, production.

The Engineering Journey of Belimo CCV Valves

Let’s uncover the fascinating engineering journey of these valves, from the drawing board to becoming a physical component in your HVAC system.

Stage 1: Conceptualization

The first stage involves identifying a specific problem or a limitation in existing valve technology. Engineers brainstorm about:

- Flow Efficiency: How can flow rates be optimized for energy conservation?

- Material Durability: What materials will offer the highest lifespan?

- Safety Features: How can automatic shut-off features be integrated?

Once the concept is solidified, it’s time to move on to the design phase.

Stage 2: Design and Prototyping

Here, the engineers draft detailed schematics, generate 3D models, and create prototypes. The design phase includes:

- CAD Modeling: Software like AutoCAD is used to create precise drawings.

- Material Selection: Based on the application, specific materials like brass or stainless steel are selected.

- Prototyping: 3D printed models might be created for initial testing.

Stage 3: Validation and Testing

Prototypes undergo a battery of tests to check their performance, durability, and safety. This stage involves:

- Flow Testing: Ensuring the valve accurately controls flow rates.

- Material Testing: Exposing the valve to corrosive elements to test its durability.

- Operational Testing: Subjecting the valve to varying temperatures and pressures.

Stage 4: Mass Production

Once the design has been validated, the valve goes into mass production. Quality control is paramount here. With each valve that comes off the assembly line, rigorous checks are conducted to ensure it meets the set standards.

Pioneering Models like b252+afrb24

When talking about standout models that represent the pinnacle of engineering in CCV valves, the b252+afrb24 can’t be overlooked. This model offers:

- High CV Value: With a CV value of 85, the valve ensures excellent flow control.

- Spring-Return Functionality: Ensures the valve returns to a safe position in case of emergencies.

- 24V On/Off Control: Simplifies the process of remote management.

Innovation and Beyond

Incorporating features like predictive maintenance, diagnostic alerts, and IoT-enabled controls, Belimo CCV Valves are a paragon of modern engineering. They’re not just designed to meet the demands of today; they’re engineered to adapt to the needs of tomorrow. Whether it’s in a sprawling industrial complex or your cozy home, these valves are sure to deliver unmatched performance, thanks to the years of engineering expertise that goes into their making.

So the next time you marvel at the efficiency of your HVAC system, take a moment to think about the incredible engineering that lies behind those small but mighty Belimo CCV Valves.

Comments